Roller Table in Steel Industry

Introduction

A roller table is a crucial handling and conveying system used in steel mills and other heavy industries to transport and manipulate hot and cold steel products between different stages of the manufacturing process. It plays a fundamental role in ensuring efficient material flow, enhancing productivity, and maintaining product quality.

Functionality

The roller table serves several essential functions in the steel industry:

- Transportation: Moves steel products, such as slabs, billets, blooms, and coils, between various processing units within the mill, including furnaces, rolling stands, cooling beds, and storage areas.

- Orientation and Positioning: Rotates and aligns steel products to facilitate further processing or inspection, ensuring they are correctly positioned for the next manufacturing step.

- Cooling and Inspection: Transports hot rolled products through cooling zones where they are gradually cooled to room temperature, essential for stabilizing metallurgical properties and preventing structural deformations.

- Accumulation and Buffering: Provides temporary storage and buffering of steel products to manage fluctuations in production rates and ensure continuous operation of downstream equipment.

- Sorting and Diversion: Diverts products to different lines or areas based on size, quality, or destination requirements within the mill.

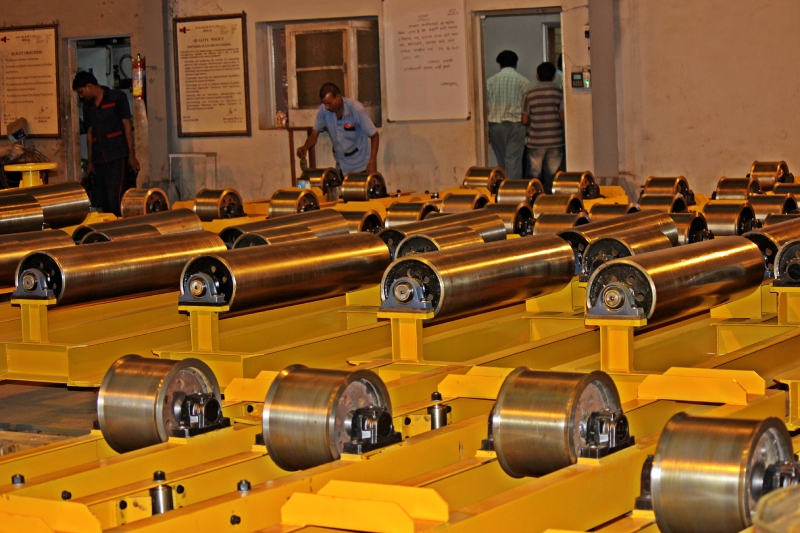

Design and Components

- Rollers: Consist of series of rollers arranged along the length of the table, usually made from durable materials such as steel or high-strength alloys, designed to support heavy loads and withstand high temperatures.

- Drive Systems: Powered by electric motors and gearboxes to provide controlled movement and precise speed regulation of steel products along the table.

- Support Structure: Features a robust framework and support beams to ensure stability and structural integrity, capable of withstanding the weight and impact of moving steel products.

- Control and Automation: Equipped with sensors, actuators, and PLC-based control systems to automate material handling processes, monitor operation parameters, and ensure seamless integration with other mill operations.

Benefits of Roller Tables

- Enhanced Efficiency: Facilitates continuous and smooth material flow, minimizing handling time and optimizing production throughput.

- Improved Product Quality: Ensures consistent handling and cooling of steel products, crucial for maintaining dimensional accuracy, surface finish, and mechanical properties.

- Operational Flexibility: Adaptable to handle various types and sizes of steel products, accommodating different production requirements and schedules.

- Safety and Ergonomics: Reduces manual handling and operator intervention, improving workplace safety and reducing the risk of injuries associated with heavy lifting and repetitive tasks.

Operational Aspects

- Integration:Installed strategically throughout the steel mill layout to connect different processing units and facilitate seamless material flow from one stage to another.

- Maintenance:Regular inspection and maintenance of rollers, drive systems, and control mechanisms are essential to ensure reliable operation and extend equipment lifespan.

- Environmental Considerations:Efforts to optimize energy efficiency and reduce environmental impact through efficient material handling practices and equipment design.

Applications

- Steel Production:Essential for handling raw materials (like iron ore, scrap) and intermediate products (slabs, billets) through various stages of steelmaking, including melting, casting, rolling, and finishing.

- Metal Processing:Used in other heavy industries for handling and processing of non-ferrous metals, such as aluminum, copper, and titanium.

Conclusion

The roller table is a fundamental component in steel mills and heavy industries, supporting efficient material handling and processing operations. Its robust design, advanced automation, and precise control capabilities contribute to enhancing productivity, maintaining product quality, and ensuring safe and sustainable manufacturing practices. As technological advancements continue, roller tables will evolve to meet the growing demands of modern steel production and metal processing industries.