Our Services

- Turnkey Project Solutions: End-to-end solutions from concept to completion for industrial projects, including project management and execution.

- Design and Engineering Services: Expertise in providing design and engineering solutions tailored to specific project requirements.

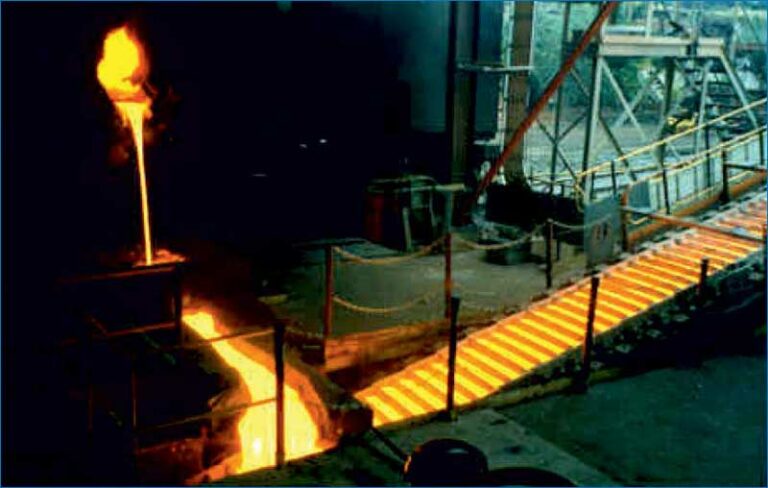

- Fabrication and Manufacturing: Capabilities in fabrication and manufacturing of steel structures, ducts, equipment, and components. Located at the heart of the steel-making area, we benefit from the most competitive steel prices.

- Erection and Commissioning: Proficiency in the erection and commissioning of industrial plants and equipment.

- Operation and Maintenance: We provide comprehensive operation and maintenance services for integrated steel plants.

- Maintenance and Refurbishment: Services encompassing maintenance, refurbishment, and optimization of industrial machinery and plants.

- Automation and Control Systems: Design, installation, and integration of automation and control systems for enhanced operational efficiency.

- Consultancy and Technical Support: Consulting services and technical support to optimize processes and enhance productivity.

- Refractory solutions tailored for all industries: Here are the varieties of refractories offered:

- Carbon Block, Bricks & Mortar: Known for high thermal conductivity and thermal shock resistance, used in blast furnace linings.

- Silica Refractory Checkers, Bricks & Mortar: High SiO2 content makes them suitable for glass-making furnaces, resistant to acidic slags.

- Fireclay Refractory Checkers, Bricks & Mortar: Composed mainly of alumina and silica, used in general-purpose applications like furnace linings.

- Magnesite Refractory Checkers, Bricks & Mortar: High MgO content ideal for steelmaking furnaces exposed to basic slags.

- Zirconia Refractory Bricks & Mortar and Pestles: Exhibits extreme refractoriness and thermal shock resistance, used in continuous casting and high-temperature reactors.

- Alumina Refractory Checkers, Bricks & Mortar: Known for high refractoriness and chemical stability, used in applications such as kiln linings.

- High-end carbon, alloy, and stainless-steel castings tailored for diverse industries: Here are the varieties of castings offered:

- Carbon Steel: Known for its strength and high wear resistance, making it suitable for diverse applications.

- Alloy Steel: Contains additional alloying elements such as manganese, nickel, chromium, and molybdenum. These elements enhance properties like strength, hardness, and corrosion resistance, tailored for specific application requirements.

- Stainless Steel: Stainless steel castings are essential in environments where resistance to corrosion is critical.

- Large Industrial Valves for Blast furnace & Cement plants: Here are the varieties of valves offered:

- Hot Blast Valve: These valves control the flow of hot air (blast) into the blast furnace. They are designed to withstand high temperatures and abrasion from the hot gases and particulates in the blast.

- Gate Valve: Gate valves are used for isolation and regulation of flow within the blast furnace system. They can withstand high temperatures and pressures typical in blast furnace operations.

- Butterfly Valve: Butterfly valves are used for controlling and throttling the flow of gases and liquids within the blast furnace system. They offer quick operation and tight shut-off.

- Check Valve: Check valves prevent backflow of gases or liquids in the blast furnace system, ensuring that flow is unidirectional and preventing damage to equipment.

- Pressure Relief Valve: Pressure relief valves protect the blast furnace system from overpressure by automatically releasing excess pressure to maintain safe operating conditions.

- Control Valve: Control valves regulate the flow, pressure, temperature, or level of gases and liquids within the blast furnace system based on signals from a control system.

- Safety Valve: Safety valves provide protection by automatically relieving pressure in case of overpressure conditions, safeguarding against potential equipment damage or failure.

- Isolation Valve: Isolation valves are used to isolate sections of the blast furnace system for maintenance, repair, or emergency shutdown purposes.

- Diaphragm Valve: Resistant to abrasion and suitable for controlling abrasive materials like cement slurry or powders. They are used in pneumatic conveying systems and for controlling process fluids.

- Knife Gate Valve: Designed for handling abrasive materials like cement clinker or powders. They provide a tight shut-off and are used in material handling systems.

- Pinch Valve: Used for controlling abrasive materials and slurries in cement plants, offering excellent sealing capabilities and resistance to wear.